Creating a future that supports safe automated driving technology

— The strength of an organization where associates learn from each other leads to steering technology

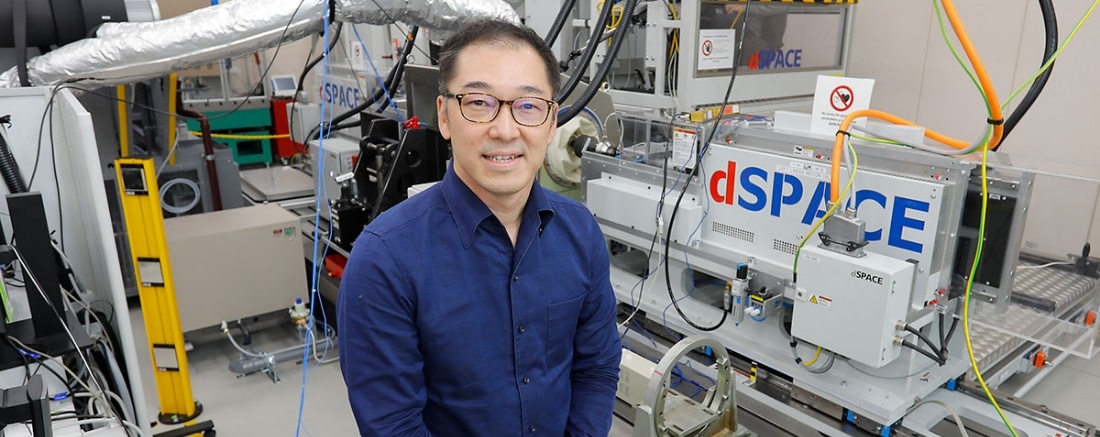

The Vehicle Motion Division (VM Division), which develops cutting-edge functions for Bosch's Electric Power Steering (EPS), is characterized by a global workplace culture in which a diverse workforce plays an active role. We asked Ko Yamamoto, head of the Steering Department, to talk about what kind of changes he envisions for the era of automated driving.

Vehicle Motion Division (VM)

Head of the Steering Department

Ko Yamamoto

Bosch's steering development initiatives and technological capabilities

Please tell us about the features of Electric Power Steering (EPS), a development area handled by the Vehicle Motion Division (hereinafter referred to as the VM Division).

To begin with, steering is a complex component that embodies the movement of the front wheels of the car and turning according to the driver's steering wheel operation. There is a sensor that senses the input from the steering wheel operation, and the Electric Power Steering (EPS) function uses an ECU and motor to electrically assist and move the rack bar. From sensing to drives, it can be said that the components for complete system control are provided within a single supplier.

There are three main functions of automobiles: running, stopping, and turning. Steering is responsible for the "turning" part, but EPS products are also in use not only when turning.

Even when the vehicle is driving straight or it is paused, the system constantly receives input from the driver's steering wheel and the front wheels of the vehicle, and constantly performs some kind of operation, such as monitoring the driver's situation, suppressing vibrations due to unevenness of the road surface, etc.

Electric Power Steering System

What are Bosch's strengths in EPS development?

Bosch excels in motor control technology. In terms of assisting the driver when turning the steering wheel, we pursue driving comfort and have earned the trust of many automobile manufacturers. It can be said that behind this is Bosch's history of development with automobile manufacturers around the world.

In response to various needs, we have responded to high demands for comfort and safety, including a hands-off function that allows the driver to let go of the steering wheel on highways and motorways, a lane keeping assist function that helps maintain the vehicle within the driving lane, and an automatic parking function. For example, in extremely cold weather, the steering wheel may freeze and become immobile. In accordance with the characteristics of the region, we have developed a wide range of technologies, such as implementing a function that prevents freezing by motor control.

In addition, there are many variations of HW "redundancy technology" looking ahead to automated driving. We take pride in the strength of Bosch's steering development, which is characterized by systems that can ensure a certain level of safety, even in the event that some kind of failure occurs the functions are not completely impaired, and we take pride in our high level of technological capabilities in a wide range of areas, from hardware to software.

Automated driving technology is making tremendous progress, and in early 2021, a Japanese automaker (OEM) became the first in the world to launch a car with Level 3 automated driving, which allows "eyes off / hands off" driving. The EPS installed in that car is our product. I think it is a very interesting product that requires an extremely wide range of knowledge for product development because there are so many functions that are necessary.

Development environment of the VM Division and the challenges of achieving automated driving

Please tell us about Bosch's unique development environment and system that supports the development of advanced steering technology.

Germany and India are responsible for the development of advanced technologies and common platforms for EPS products, while regions such as Japan and North America, where automobile manufacturers are located, are responsible for development for finished cars. We proceed with development while maintaining close coordination between the advanced technology side, which is responsible for new ideas, and each region, which ascertains the future needs of the vehicle manufacturers. Experts in each field, and experts on the vehicle manufacturer project side, are well assigned globally, and a network has been established to share knowledge and the latest information.

EPS products have such a wide range of functions that one person cannot know them all. By having a place where associates can gather and communicate as necessary, I believe that the foundation is in place for the entire business division to overcome challenges.

What are some of the current challenges in steering development?

Bosch still has a lot of room to provide technology to Japanese automobile manufacturers. In recent years, the need for our high redundancy technology and driver assistance technology has increased significantly, and even at Bosch there are growing expectations for a development system that can support the development of automakers in Japan. There is an urgent need to create a system that enables us to quickly and jointly develop advanced technologies with automobile manufacturers locally in Japan.

The construction of a new line at the Saitama Musashi Plant is one of the ways to meet the needs of domestic automobile manufacturers.

What is your vision of future steering product strategies and challenges?

I believe that the steer-by-wire technology, which is necessary to realize Level 5 automated driving, will be a new technology challenge for Bosch as well. Steer-by-wire eliminates the conventional mechanical parts that were used to link the steering wheel to the front wheels of a vehicle. Instead, steer-by-wire is a direct control system in which driver input is sent via electrical signals to the rack actuators on the front wheel side of the vehicle, to control the angle of the front wheels.

Today's steering wheel could become like a game controller, with the front wheels moving automatically in response to driver input and vehicle conditions. It can be said that it is one of the technologies that will lead to automated driving in the future. In addition to automated driving, the potential will also expand for integrated control of vehicle dynamics combined with brakes and electric vehicle powertrains.

Bosch has a development environment for systems that control automobiles in an integrated manner, from brake control to steering technology. We would like to continue to maintain as our strength the high potential to connect core technologies and make proposals to automobile manufacturers.

Workplace environment and distinctive culture in which global members play an active role

Mr. Yamamoto, I heard that you have been in the VM Division since you joined Bosch. Why did you decide to join Bosch mid-career and what work you have been in charge of at Bosch so far?

After working as a mechanical design engineer at a Japanese steering manufacturer for about fifteen years, I joined Bosch's Vehicle Motion Division mid-career in 2016. After working as a Technical Project Manager (TPM), Manager of the Customer Group (TPM, System and Mechanics), and Manager of Hardware Development and Software Development for ECU and Motors in the Electrical Engineering Department, I became General Manager of the department in 2021, and Head of the Steering Department since January 2023.

In my previous job, I was in charge of a European automobile manufacturer, so I had many opportunities to hear about Bosch's world-leading technological capabilities and high product quality, and I had a strong interest in Bosch. In addition, having lived in the United States for four and a half years, I wanted to work in a global environment. I decided to join Bosch, where I can experience "high technology x global operations".

How did your expectations change since you actually joined Bosch?

Bosch is more dynamic than I imagined. Bosch is committed to always making a difference in the world and values the attitude of making changes happen. I was amazed by the enthusiasm for developing new ideas, and the activeness in bringing products to market.

In my previous job, the corporate culture was to be meticulous in our preparations to avoid risks. However, as the product environment and the market itself are changing rapidly, the decision-making speed at Bosch is quick, such as "let's try it" and "let's take on challenges". It is very exciting.

In addition, my position changes every few years, and the range of challenges I take on is expanding. It has been seven years since I joined Bosch, and I never get tired of it.

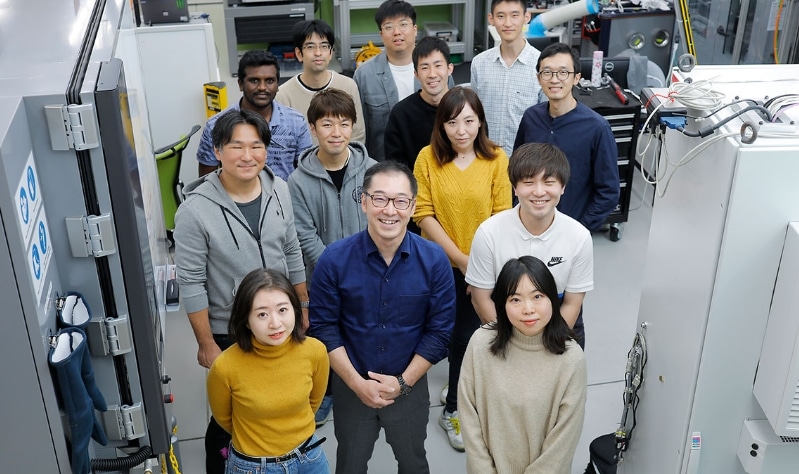

Bosch has associates with diverse backgrounds and nationalities. The culture that is born from this is also connected to the strength of the organization.

I work with members from Germany and other European countries, India, Vietnam, and North America, and they all have different strengths. There are members who are skilled at thinking theoretically and giving shape to ideas, flexible members who try to solve problems by working agilely, and so on. Every day I feel an energy and diversity that is different than with Japanese associates.

There is one project team per car model, and in large projects, there are times when the team works with nearly 100 people. Approximately 10 to 20% of the members are Japanese. The process of teaming up with multinational members to create a single product is a dynamic that is unique to Bosch, which develops products on a global scale.

Are there any organizational characteristics unique to the VM Division?

Mid-career hires account for 90% of the Steering Department. The division has associates with diverse backgrounds and diverse skills and experiences, including former design engineers at automobile manufacturers and parts manufacturers, software engineers at home appliance manufacturers, and people from copy machine manufacturers.

There is a culture of helping each other by sharing each other's expertise and experience openly through communication. I think it is a very comfortable environment for mid-career hires.

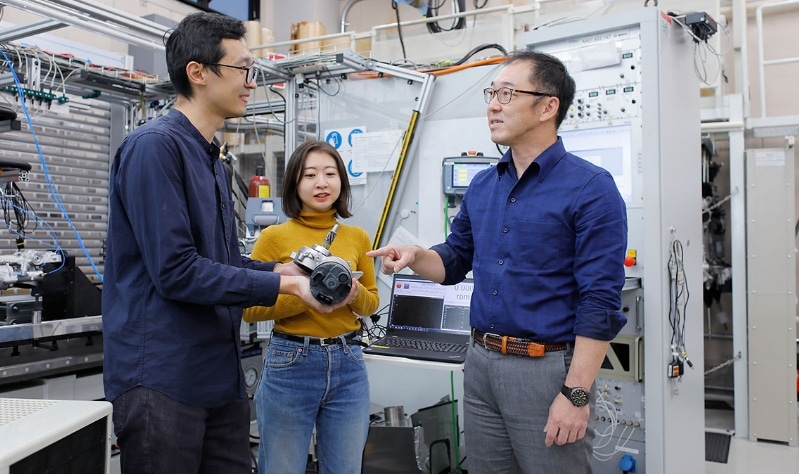

How do associates share their skills and experiences?

In our daily work, we share ideas based on each other's knowledge, and study sessions are held by volunteers in each group. In one department's periodic meetings, members take turns each week to share "non-work topics". I hope that talking about what you like and what you are into will spark conversations and lead to team strength by understanding the individuality of the members.

What is appealing and rewarding about working as an engineer at Bosch?

What kind of skills, experience, and personality are you looking for in engineers, with whom you want to work with in the future?

The field of specialization does not matter, but it is desirable to have experience in product design and development, and want to take on new challenges by making the most of your own strengths. In this era where the automotive industry is facing transformation, I think it is suitable for those who want to work on new technological development while interacting with people from all over the world.

You may think that a high level of English proficiency is necessary because it is a global company, but I was not that good at English either. English skills can be improved through daily communication and effort. First of all, I would like to know what kind of development experience you have and what you want to achieve after joining Bosch.

A global environment where you can develop with members with diverse specialties broadens your horizons. At Bosch, communicating with associates around us often makes us realize, "There is such a technology." or "There is such an idea." I myself have been able to move forward through discussions with various members, and I feel that I am learning the depth and breadth of Bosch's technological strengths.

Do you have a message for engineers who want to work at Bosch?

Bosch has a culture of "designing your own career". If you have a concrete image of the skills and experience you want to acquire, there is a good environment for training, including study sessions. Even in the development field, all members are given the opportunity to play a role in technological innovation, and there is an environment where associates can participate if they want to.

The expectations of Japanese automobile manufacturers for Bosch are getting bigger and bigger. Electric power steering is a cutting-edge function that will support future automated driving technology and vehicle dynamics technology. It can be said that the experience of creating the future is of enormous value.

* Photographed at Bosch Corporation Yokohama Fourth Office

*Information contained in this article is current at the time of the interview. (Published on January 23, 2023)